Most industrial lifting processes prefer using wire rope slings because they are durable, robust, and have a high temperature limit. Remember that most reputable wire rope sling hiring companies like Lakeside Hire usually keep wire rope slings that are resistant to the abrasion process and are flexible.

You can decide to use thimbles as it increases the lifespan of the ropes. This protects the ropes, especially at the connecting points to ensure they are quite secure and last longer. Even better, the slings tend to have the required corrosion resistance, making them suitable in a wide range of industries. This article discusses what you should know before you hire wire rope slings.

Using Wire Rope Slings

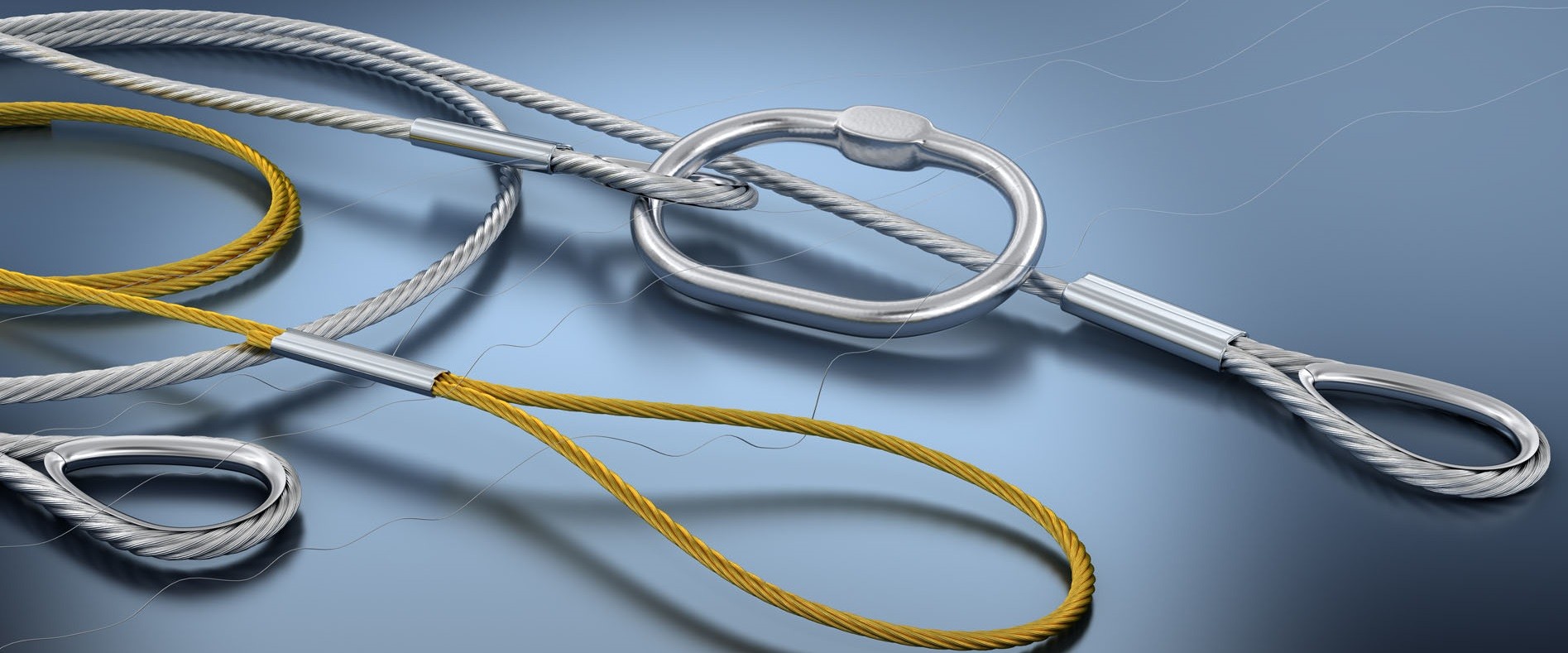

Wire rope slings are a crucial piece of rigging hardware in most industries and it’s utilized in hoisting and lifting operations. These slings can connect the load to a lifting device and you can find them in a variety of configurations that support a wide range of applications. You should note that these configurations can have single and multi-part slings like flat braids, round braids, and cable laid slings.

Wire rope slings are often preferred when it comes to heavy load lifting operations which is common in most construction sites, marine industry, shipyards, and many more. You need to note that this is also an important rigging part in the manufacturing industry because it needs heavy duty lifting, loading, and shifting of heavy items. These loads tend to vary in size and shape, but this depends on the manufacturing activities they are being used for.

_product_feature.jpg?1484145879)

You should remember that the manufacturing industry is similar to industrial and engineering design, but it can also include a variety of activities like production, packing, and sales of products. Choosing the right wire rope slings can depend on the application of it in any of these activities.

The Wire Rope Sling Designs

Wire rope sling categories are usually named after the design of the sling and the number of wires that are in a strand and the number of strands that are wrapped around its core. One of the types of slings that are utilized in the manufacturing industry is the eye and eye sling. In most cases, this is utilized in basket, vertical, and choker hitches, and there is the oval eye at both sides of the sling. These rope slings are reliable and rugged and a quite popular option because of their versatility.

There are also bridle slings that are designed to do general lifting. You can directly connect them to the load by simply hooking into the eyes or even placing the loops over projections. These are suitable for handling loads, but there should be fixed lifting points.

Another type of wire rope slings is a nine-part sling that is especially effective with large and heavy loads. This is because their weight is distributed evenly among its nine parts. The construction of this wire rope string allows for easy inspection of a wire rope, which is important when you decide to reuse the sling for several loads. You can also use them in heavy duty loading activities, especially in the manufacturing industry.